Product Description

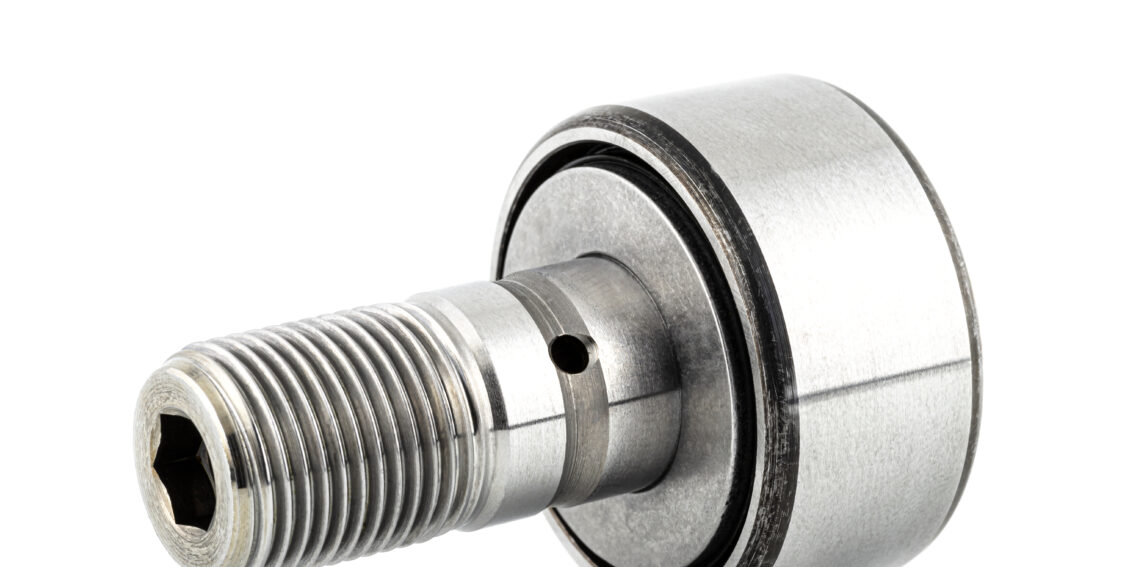

CF-1 1/2-B Stud Type Track Rollers Cam Follower Bearing For Machine Tools

Application

Metals Mining, Mineral Processing and Cement

Railways Industrial Applications.

Material Handling Agriculture

Construction Machine Tools

Auto Parts Power Generators

Cam Followers Stud-Type Track Rollers are designed to run on all types of tracks and to be used in cam drives, conveyor systems, etc.

They are based on either needle or cylindrical roller bearings. Instead of an inner ring, they have a threaded CHINAMFG stud (pin)

CF B serial cam follower bearing Specification

| Product Name | CFVBR CFVBUUR Stud Type Track Rollers |

| Precision Rating | P6, P0, P5, P4, P2 |

| Material | Bearing Steel (GCr15) |

| Clearance | C1 C2 C3 |

| Vibration & Noisy | Z1, Z2, Z3 V1, V2, V3 |

| Features | With Axial Guidance, Axial Plain Washers on Both Sides,full complement needle roller set |

| CFVBR Features | Shiled Type |

| CFVBUUR Features | Sealed Type |

| Application | Machine Tools, Auto Parts, Power Generators,and other Industrial Applications |

| Certification | ISO 9001: 2008 |

| Packing | 1. Neutral Packing Bearing 2. Industrial Packing 3. Commercial Packing Bearing 4. Customize |

| Delivery Time | 30 – 45 Days After The Order is Confirmed |

| Shippment | 1. By Sea 2. By Air 3. By Express |

| CF | V | B | UU | R |

| Standard Type | Full Complement Type | Hexagon Socket | Sealed Type | Crowned Outer Ring |

CF B serial cam follower bearing Specification

| Bearing No. | Dimensions (mm) | Basic Load Rating(KN) | Limited Speed |

Mass | |||||||||

| Hexagon Hole | Sealed Type | D | d | C | B | B1 | B2 | G | G1 | C | Co | rpm | kg |

| CF-1/2-N-B | CF-1/2-N-SB | 12.70 | 4.83 | 8.73 | 22.23 | 12.70 | – | 10-32 | 6.35 | 3.44 | 3.84 | 12000 | 0.009 |

| CF-1/2-B | CF-1/2-SB | 12.70 | 4.83 | 9.53 | 26.19 | 15.88 | – | 10-32 | 6.35 | 3.84 | 4.40 | 12000 | 0.571 |

| CF-9/16-B | CF-9/16-SB | 14.29 | 4.83 | 9.53 | 26.19 | 15.88 | – | 10-32 | 6.35 | 4.30 | 5.30 | 10000 | 0.015 |

| CF-5/8-N-B | CF-5/8-N-SB | 15.88 | 6.35 | 10.32 | 26.99 | 15.88 | – | 1/4-28 | 7.94 | 4.72 | 6.24 | 8800 | 0.019 |

| CF-5/8-B | CF-5/8-SB | 15.88 | 6.35 | 11.11 | 30.96 | 19.05 | – | 1/4-28 | 7.94 | 5.20 | 7.00 | 8800 | 0.571 |

| CF-11/16-B | CF-11/16-SB | 17.46 | 6.35 | 11.11 | 30.96 | 19.05 | – | 1/4-38 | 7.94 | 6.50 | 8.50 | 8000 | 0.030 |

| CF-3/4-B | CF-3/4-SB | 19.05 | 9.53 | 12.70 | 35.72 | 22.23 | 6.35 | 3/8-24 | 9.53 | 7.12 | 10.00 | 6400 | 0.037 |

| CF-7/8-B | CF-7/8-SB | 22.23 | 9.53 | 12.70 | 35.72 | 22.23 | 6.35 | 3/8-24 | 9.53 | 7.12 | 10.00 | 6400 | 0.048 |

| CF-1-B | CF-1-SB | 25.40 | 11.11 | 15.88 | 42.07 | 25.40 | 6.35 | 7/16-20 | 12.70 | 10.64 | 18.50 | 5200 | 0.076 |

| CF-1 1/8-B | CF-1 1/8-SB | 28.58 | 11.11 | 15.88 | 42.07 | 25.40 | 6.35 | 7/16-20 | 12.70 | 10.64 | 18.50 | 5200 | 0.087 |

| CF-1 1/4-B | CF-1 1/4-SB | 31.75 | 12.70 | 19.05 | 51.59 | 31.75 | 7.94 | 1/2-20 | 15.88 | 19.20 | 25.90 | 4400 | 0.140 |

| CF-1 3/8-B | CF-1 3/8-SB | 34.93 | 12.70 | 19.05 | 51.59 | 31.75 | 7.94 | 1/2-20 | 15.88 | 19.20 | 25.90 | 4400 | 0.163 |

| CF-1 1/2-B | CF-1 1/2-SB | 38.10 | 15.88 | 22.23 | 61.12 | 38.10 | 9.53 | 5/8-18 | 19.05 | 23.00 | 32.70 | 3600 | 0.235 |

| CF-1 5/8-B | CF-1 5/8-SB | 41.28 | 15.88 | 22.23 | 61.12 | 38.10 | 9.53 | 5/8-18 | 19.05 | 23.00 | 32.70 | 3600 | 0.270 |

| CF-1 3/4-B | CF-1 3/4-SB | 44.45 | 19.05 | 25.40 | 70.64 | 44.45 | 11.11 | 3/4-16 | 22.23 | 28.70 | 45.40 | 3200 | 0.379 |

| CF-1 7/8-B | CF-1 7/8-SB | 47.63 | 19.05 | 25.40 | 70.64 | 44.45 | 11.11 | 3/4-16 | 22.23 | 28.70 | 45.40 | 3200 | 0.426 |

| CF-2-B | CF-2-SB | 50.80 | 22.23 | 31.75 | 83.34 | 50.80 | 12.70 | 7/8-14 | 25.40 | 37.30 | 65.80 | 2800 | 0.640 |

| CF-2 1/4-B | CF-2 1/4-SB | 57.15 | 22.23 | 31.75 | 83.34 | 50.80 | 12.70 | 7/8-14 | 25.40 | 37.30 | 65.80 | 2800 | 0.774 |

| CF-2 1/2-B | CF-2 1/2-SB | 63.50 | 25.40 | 38.10 | 96.04 | 57.15 | 14.29 | 1-14 | 28.58 | 54.00 | 102.30 | 1.126 | |

| CF-2 3/4-B | CF-2 3/4-SB | 69.85 | 25.40 | 38.10 | 96.04 | 57.15 | 14.29 | 1-14 | 28.58 | 54.00 | 102.30 | 1.316 | |

| CF-3-B | CF-3-SB | 76.20 | 31.75 | 44.45 | 108.70 | 63.50 | 15.88 | 1 1/4-12 | 31.75 | 72.30 | 155.00 | 1.905 | |

| CF-3 1/4-B | CF-3 1/4-SB | 82.55 | 31.75 | 44.45 | 108.70 | 63.50 | 15.88 | 1 1/4-12 | 31.75 | 72.30 | 155.00 | 2.170 | |

| CF-3 1/2-B | CF-3 1/2-SB | 88.90 | 34.93 | 50.80 | 121.40 | 69.85 | 17.46 | 1 3/8-12 | 34.93 | 104.80 | 196.70 | 2.878 | |

| CF-4-B | CF-4-SB | 101.60 | 38.10 | 57.15 | 146.80 | 88.90 | 19.05 | 1 1/2-12 | 38.10 | 138.00 | 278.00 | 4.253 | |

| CF-5-SB | 127.00 | 50.80 | 69.85 | 200.00 | 128.60 | 22.23 | 2-12 | 65.07 | 214.00 | 422.00 | |||

| CF-6-SB | 152.40 | 63.50 | 82.55 | 236.50 | 152.40 | 25.40 | 2 1/2-12 | 76.20 | 276.00 | 500.00 | |||

| CF-7-SB | 177.80 | 76.20 | 95.25 | 292.00 | 195.25 | 31.75 | 3-12 | 104.80 | 347.00 | 665.00 | |||

| CF-8-SB | 203.20 | 82.55 | 107.95 | 327.00 | 215.90 | – | 3 1/4-4 | 108.15 | 424.00 | 896.00 | |||

| CF-9-SB | 228.60 | 95.25 | 120.65 | 365.10 | 241.30 | – | 3 1/2-4 | 120.65 | 521.00 | 1140.00 | |||

| CF-10-SB | 254.00 | 107.95 | 133.35 | 390.50 | 254.00 | – | 3 1/2-4 | 120.65 | 605.00 | 1340.00 | |||

About Us

HENGLI Machinery Company is a well-established Chinese bearing supplier. We design, manufacture and wholesale bearings.

Our specialized manufacturer of Spherical Roller Bearing & Cylindrical Roller Bearing, XIHU (WEST LAKE) DIS. Rolling Bearing Co., Ltd was

established in 1970 and is accredited by the Chinese Ministry of Machine Building.

We invested in 2 additional specialized bearing factories, which allow us to provide our clients with top of the line products

such as Needle Roller Bearings, Cam Follower Bearings, Thrust Bearings, Spherical Plain Bearings, Rod Ends Bearings,

Ball Joint Bearings,Tapered Roller Bearings, Wheel Hub Bearings and Non-Standard Bearings.

FAQ

Q1 – What is our advantages?

A – Manufacturer – Do it only with the Best;

-Your Choice make different.

Q2 – Our Products

A – Spherical Roller Bearing, Cylindrical Roller Bearing, Needle Roller Bearing, Cam Followers, Thrust Bearing

– Spherical Plain Bearing, Rod End, Ball Joint, Wheel Hub, Tapered Roller Bearing

Q3 – Process of our production

A – Heat Treatment – Grinding – Parts Inspection – Assembly – Final Inspection – Packing

Q4 – How to customize bearing(non-standard) from your company?

A -We offer OEM, Customized(Non-standard) service and you need to provide drawing and detailed Technical Data.

Q5 – What should I care before installation?

A – Normally, the preservative with which new bearings are coated before leaving the factory does not need to be

Removed; It is only necessary to wipe off the outside cylindrical surface and bore, if the grease is not compatible

With the preservative, it is necessary to wash and carefully dry the bearing.

-Bearings should be installed in a dry, dust-free room away from metal working or other machines producing

Swarf and dust.

Q6 – How to stock and maintenance my bearings right?

A – Do not store bearings directly on concrete floors, where water can condense and collect on the bearing;

-Store the bearings on a pallet or shelf, in an area where the bearings will not be subjected to high humidity

Or sudden and severe temperature changes that may result in condensation forming;

-Always put oiled paper or, if not available, plastic sheets between rollers and cup races of tapered roller bearings.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Material: | Bearing Steel |

| Spherical: | Non-Aligning Bearings |

| Load Direction: | Radial Bearing |

| Separated: | Unseparated |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What safety considerations should be taken into account when using cam rollers in industrial settings?

When using cam rollers in industrial settings, several safety considerations should be taken into account to ensure the well-being of personnel, prevent accidents, and maintain a safe working environment. Here are some important safety considerations when using cam rollers:

- Proper Guarding: Cam rollers should be properly guarded to prevent accidental contact with moving parts. Depending on the specific application and the level of exposure, appropriate guarding measures such as barriers, enclosures, or safety covers should be in place to protect operators and other personnel from potential hazards associated with rotating cam rollers.

- Lockout/Tagout Procedures: Before performing maintenance or repair tasks on cam rollers or associated equipment, appropriate lockout/tagout procedures should be followed. Lockout/tagout procedures help ensure that energy sources are isolated, machinery is de-energized, and appropriate warning devices are in place to prevent unintentional startup or release of stored energy, minimizing the risk of injury.

- Training and Awareness: Adequate training should be provided to operators and maintenance personnel working with cam rollers. They should be trained on safe operating procedures, potential hazards, emergency protocols, and proper use of personal protective equipment (PPE). Regular refresher training sessions and ongoing awareness programs can help reinforce safe practices and promote a safety-conscious culture.

- Risk Assessment: Conducting a thorough risk assessment specific to the application and environment is crucial. Identify potential hazards associated with cam rollers, such as pinch points, entanglement risks, or flying debris. Assess the severity of each hazard and implement appropriate control measures to mitigate the risks, such as installing physical barriers, implementing safety interlocks, or providing warning signage.

- Maintenance and Inspections: Regular maintenance and inspections of cam rollers are essential for identifying and addressing any issues that may compromise safety. Inspect the rollers, bearings, tracks, and associated components for signs of wear, damage, or misalignment. Follow manufacturer recommendations for maintenance intervals, lubrication schedules, and component replacements to ensure the safe and reliable operation of cam rollers.

- Proper Load Handling: Ensure that cam rollers are not subjected to loads or forces beyond their specified capacity. Overloading cam rollers can lead to premature wear, component failure, or dangerous conditions. Consider the weight, size, and distribution of the load being tracked and ensure that the cam rollers and associated components are designed to handle the applied loads safely.

- Proper Installation and Alignment: Follow proper installation procedures and ensure accurate alignment of cam rollers. Improper installation or misalignment can result in unexpected movements, excessive friction, or component failures, posing safety risks. Adhere to manufacturer guidelines and recommended alignment procedures to ensure safe and reliable operation.

- PPE Usage: Personal protective equipment (PPE) should be provided and used appropriately by personnel working with or in the vicinity of cam rollers. Depending on the specific hazards involved, PPE such as safety glasses, gloves, hearing protection, or safety shoes may be required to mitigate the risk of injuries due to flying debris, contact with moving parts, noise exposure, or other potential hazards.

It is important to consult relevant safety regulations, industry standards, and guidelines specific to the application and location to ensure full compliance with safety requirements when using cam rollers in industrial settings. Regular safety audits, hazard assessments, and open communication with personnel can help identify and address potential safety concerns, creating a safer working environment for everyone involved.

Can cam rollers be customized for specific industries or machinery configurations?

Yes, cam rollers can be customized to meet the specific requirements of different industries or machinery configurations. The versatility and adaptability of cam rollers make them suitable for a wide range of applications. Customization allows for the optimization of cam rollers to match the unique needs of various industries and machinery configurations. Here’s a detailed explanation of how cam rollers can be customized:

- Size and Dimensions: Cam rollers can be customized in terms of size and dimensions to suit specific machinery configurations. The outer diameter, inner diameter, width, and overall dimensions of the cam roller can be adjusted to fit within the available space and align with the requirements of the machinery or system.

- Load Capacity: Customization of cam rollers can involve enhancing the load-carrying capacity to meet the demands of specific industries or heavy-duty applications. By utilizing different materials, heat treatments, or bearing arrangements, cam rollers can be designed to withstand higher radial and axial loads, ensuring reliable performance under challenging operating conditions.

- Specialized Coatings and Materials: Certain industries or environments may require cam rollers with specialized coatings or materials to withstand corrosive or abrasive conditions. Customization can involve the application of coatings, such as corrosion-resistant coatings or low-friction coatings, to enhance the durability and performance of the cam rollers in specific operating environments.

- Sealing Options: Cam rollers can be customized with various sealing options to provide protection against contaminants, dust, moisture, or other environmental factors. Custom sealing arrangements, such as rubber seals or labyrinth seals, can be incorporated into the design to ensure the longevity and reliability of the cam rollers in specific industries or applications.

- Attachment and Mounting: Customization of cam rollers can include modifications to the attachment and mounting options. Different industries or machinery configurations may require specific attachment methods or mounting configurations. Cam rollers can be customized with different stud types, yoke configurations, or eccentric collar options to ensure easy and secure attachment to the moving parts of the machinery or system.

- Specialized Performance Features: Depending on the industry or application, cam rollers may need specialized performance features. Customization can involve incorporating features such as integrated lubrication systems, temperature sensors, or shock-absorbing elements to enhance the performance, reliability, or monitoring capabilities of the cam rollers in specific industries or machinery configurations.

By collaborating with manufacturers or suppliers, industries can work to customize cam rollers to meet their specific requirements. Customization may involve engineering analysis, design modifications, and material selection to ensure the optimal performance and compatibility of the cam rollers with the targeted industries or machinery configurations.

In summary, cam rollers can be customized for specific industries or machinery configurations. Customization options include adjusting size and dimensions, enhancing load capacity, utilizing specialized coatings and materials, incorporating sealing options, modifying attachment and mounting methods, and adding specialized performance features. By tailoring cam rollers to specific industry or machinery needs, customization ensures optimal performance, longevity, and compatibility with the targeted applications.

Can you explain the primary functions and roles of cam rollers in various applications?

Cam rollers, also known as cam followers or track rollers, serve a variety of functions and play crucial roles in various applications across different industries. These specialized roller bearings are designed to follow the surface profile of a cam or track, enabling them to transmit motion, provide guidance, support, and handle loads. Here’s a detailed explanation of the primary functions and roles of cam rollers in various applications:

- Motion Transmission: One of the primary functions of cam rollers is to transmit motion from a rotating cam to a reciprocating or oscillating component. They are commonly used in applications such as engines, where they transfer the motion of the camshaft to the valves, controlling the opening and closing of the valves at the appropriate timing. Cam rollers ensure precise and reliable motion transmission in these systems.

- Guidance and Support: Cam rollers are frequently utilized to provide guidance and support to moving components in mechanical systems. They help maintain proper alignment and prevent lateral movement or deflection. In conveyor systems, for example, cam rollers guide the movement of belts or chains, ensuring smooth and controlled operation.

- Load Bearing: Cam rollers are designed to bear high loads and provide support in heavy-duty applications. They are commonly found in machinery and equipment where there is a need for reliable load-bearing capabilities. Construction machinery, material handling equipment, and industrial automation systems often rely on cam rollers to handle substantial loads and ensure stable and efficient operation.

- Compensating for Misalignment: In some applications, cam rollers are employed to compensate for misalignment between components. The rolling motion of the cam follower allows it to adjust and accommodate slight deviations in the cam or track profile. This feature ensures smooth operation even when there are minor misalignments, improving the overall performance and reliability of the system.

- Application-Specific Functions: Cam rollers can also serve application-specific functions based on the requirements of a particular system. For example, in printing and packaging machinery, cam rollers may be used to control the tension and guide the movement of printing substrates or packaging materials. In textile machinery, cam rollers may play a role in controlling the feeding and positioning of fabrics. The versatility of cam rollers allows them to be tailored to the specific needs of diverse applications.

The choice of cam roller design, size, and material depends on the specific demands of the application. Factors such as load capacity, speed, operating conditions, precision requirements, and environmental factors are taken into consideration when selecting the appropriate cam roller. Regular maintenance, including lubrication and inspection, is vital to ensure optimal performance and longevity of cam rollers in various applications.

In summary, cam rollers fulfill essential functions and play significant roles in a wide range of applications. They enable motion transmission, provide guidance and support, bear heavy loads, compensate for misalignment, and serve application-specific functions. Cam rollers contribute to the efficiency, reliability, and smooth operation of mechanical systems across diverse industries.

editor by CX 2024-04-13